About Us

Backed by extensive industry experience for more than 40 years, we are successfully meeting the demands of the pump industry. State of the art facility, continuous Research & Development, introduction of latest techniques and methodologies are the driving force behind the success of our company. We believe that superior quality of our products, their competitive prices and timely delivery are the outstanding features that attract customers to stay for years together & provide referrals. Our in-depth market understanding of the ever changing needs of clients have enabled us understand and ensure on-time delivery of superlative products and services that matches their needs. Our commitment to sustainability and systematic approach to problem solving has led to continued growth.

Over The Years

Our Vision

To establish Raja Engineering Works as a leader in sustainable manufacturing, delivering exceptional value to all stakeholders through continuous improvement across all areas of the business.

Our Mission

To provide high-quality products and solutions that exceed customer expectations, drive innovation, and continuously improve every aspect of our business through standardisation. We are committed to fostering a culture of collaboration, integrity, and social responsibility, while ensuring long-term value for our stakeholders.

Our Partners

Thiagarajan S

Managing Partner

Sampath K

Managing Partner

B.E. in Production Engineering from PSG College of Technology, M.S in Industrial Engineering from University of Cincinnati, USA. His variety of exposure both in the field of manufacturing and IT has enabled him to implement ISO systems as well as ERP systems to monitor and improve the overall inventory planning, implement J.I.T. production. The core areas of his management include design, inventory planning, marketing and customer service.

Our Founders

Kanakaraju A

Founder Partner

Sundararajan A

Founder Partner

Got his training at one of the premier holistic technical institute, Artisan Training Institute, Ambernath, a division of Ministry of Defence. After which, he went on to get the most wanted technical experience of more than 10 years in Ordinance Factory in tool design and manufacturing. This plethora of experience paved the corner stone of our precision press shop, rubber moulding and highly efficient assembly divisions.

“Assuring The Quality At Every Stage”

Our products are used in majority of water pump applications that demands the highest standards of performance and reliability. We believe quality of the products and services play a key role in achieving customer satisfaction. Being a quality conscious company, we have always given prime importance to maintain precision & quality. By making use of the advanced testing machines we adopt stringent quality control measures at all stages of production & conform to the requirements of our customers. Following are some of the tests we perform to meet customer requirements.

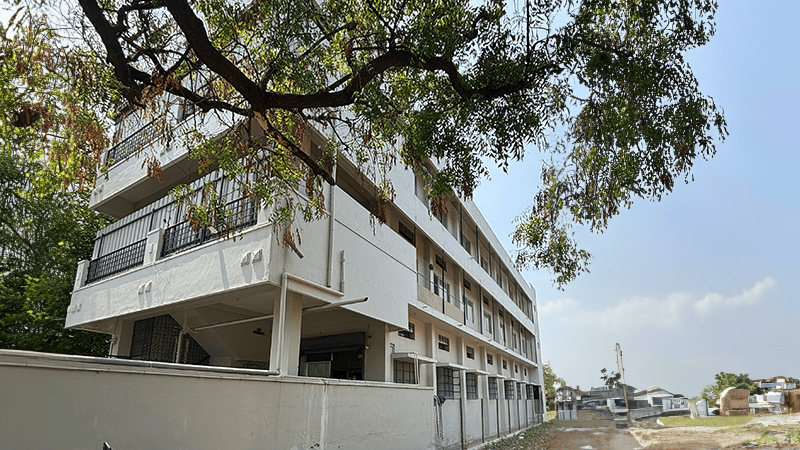

"Equipped For Precision Manufacturing"

The company is fully integrated with best of technology available for design & production of precision mechanical seals. The company is equipped with state of the art facilities in-house, to produce wide range of mechanical seals. The sophisticated tool room and press shop facilitate the production of cost effective, precise components. The imported automatic vacuum compression moulding machines drive our elastomer production consistently with quality and quantity. We also offer customised elastomeric components to suit your pumping needs with the help of our in-house rubber compounding and high precision moulding. Our seal rings are surface finished and polished with high tech lapping machine. Our Facility includes precision finishing machines like: